Elastic denim manufacturer: elastic denim shrinkage recovery ability

Elasticity in elastic denim refers to the ability to recover the shape of denim when the external force causing the deformation of denim is removed. The stretching of denim can be divided into unidirectional stretching and biaxial stretching. Uniaxial tensile means that the specimen increases along the tensile direction, while the dimension perpendicular to the tensile direction decreases. Biaxial stretching is stretching in two vertical directions at the same time, or in one direction. In the direction perpendicular to the tension, the size of the specimen is forced to remain unchanged.

Like other textile materials, elastic denim deformation is composed of three parts, namely, rapid elastic deformation, slow elastic deformation and plastic deformation. Rapid elastic deformation is the part that occurs when the load is added and disappears immediately after the load is removed. Slow elastic deformation is the part that increases with time after the load is added, but decreases gradually after the load is removed and disappears after time. Plastic deformation is due to the irrecoverable deformation part in the fiber or yarn microstructure.

The influence of different weave structure, different knitting tension and different knitting needle specifications in elastic denim on the instantaneous elastic recovery and delayed elastic recovery of elastic fabric in the longitudinal and transverse directions.

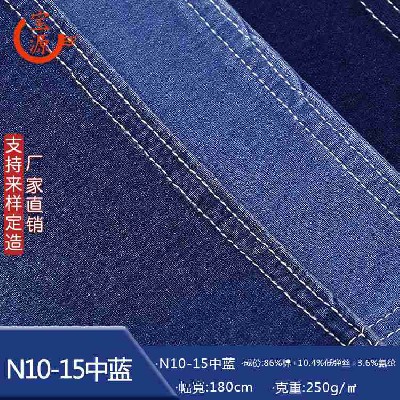

Elastic denim is made by adding elastic fibers in the weft, warp or both directions, such as spandex covered yarn, PBT, T-400, etc. Make denim clothing not only fit, comfortable, but also move freely. The elastic elongation is generally 20% - 40%, and its size is closely related to the fabric structure. The smaller the warp and weft tightness of the fabric, the greater the elasticity. In the case of warp tension, the greater the tension of weft elastic yarn, the smaller the elasticity; The weft tightness reaches the degree, and even the elasticity will be lost.

Due to the problem of excessive weft shrinkage of the finished elastic denim fabric, which is generally more than 10%, some even more than 20%, the unstable fabric width brings great inconvenience to the clothing production. Therefore, 20% - 30% is generally used in product design. Keep the tension of elastic denim in the warp and weft directions, properly increase the tension during the preshrinking finishing, so that the fabric width has a large shrinkage, and thus obtain a lower residual shrinkage in the weft direction of the finished fabric. It is also possible to heat set the elastic denim fabric after pre-shrinking, so as to obtain a uniform cloth width and a stable and low weft shrinkage.

Article source: elastic denim manufacturer http://mkiller.cn

-

10-15

Knitted denim factory: weaving process of knitted denim

Weaving technology of knitted jeansThe application of knitted jeans in life can be said to be many, and the advantages of knitted jeans are also many, so it has been widely used in the clothing indust

-

07-08

The knitting denim factory introduces the washing methods and types

1. General washing means general washing. It's just to change the washing we know about everyday to mechanization. The water temperature is about 60 ° - 90 ° C, and a certain amount of detergent

-

04-08

Characteristics of coated denim

Coated denim refers to a kind of post-processing product of denim, which is evenly coated with macromolecular compounds that can form a film on the surface of denim to change the appearance, style or

-

03-04

The reason why elastic jeans have elasticity

Now we all love beauty and attach importance to the maintenance of body shape. Many people will choose some elastic clothes to highlight the curve when they have attractive body shape. Elastic jeans h